Our value chain (1)

From production site to factory gate

How does a substrate actually get from the production site to the horticultural company and from there to the consumer? What milestones do the raw peat materials cross in the course of this journey? Two articles describe the path of our raw materials and our products from the place of origin to their final destinations. The first part presents the route from the production sites to the factory gates.

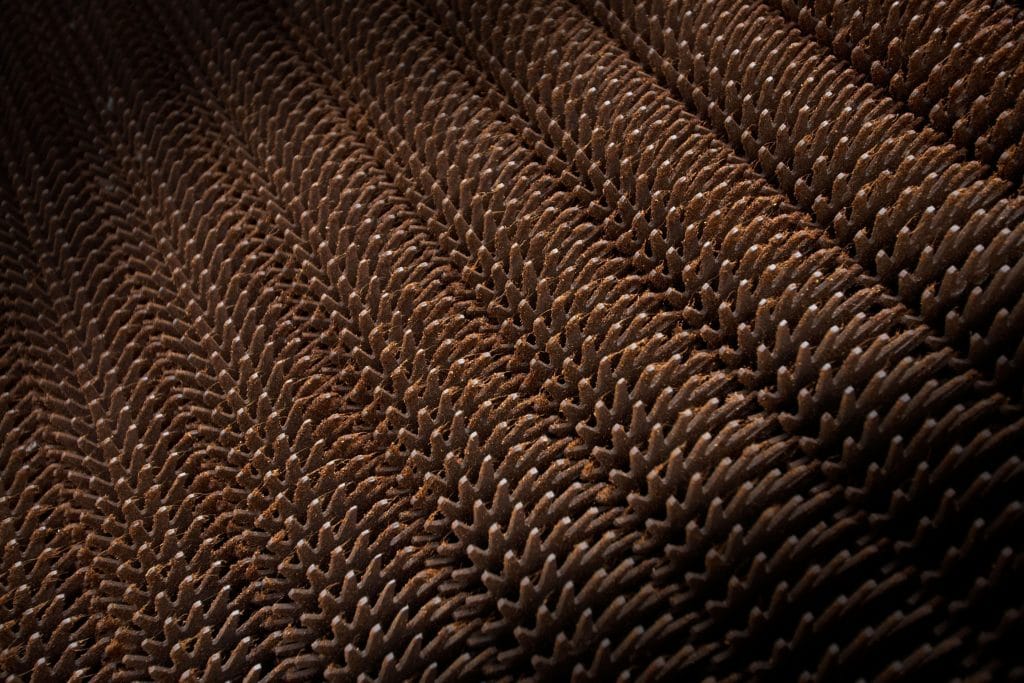

Transport to the production plants: Frozen black peat and milled peat are piled into stacks and stored at the extraction sites and transported from there to the bog railway line, for instance with the “bog shuttle”, a gigantic transport machine that is unique to Klasmann-Deilmann. Our bog railway systems are designed as narrow-gauge railways to cope with the difficult conditions at the extraction sites. They are used to carry the peat to the production facilities.

Mixing and dosing systems: Each product is made up according to a specific recipe which has its own recipe number. We can, of course, produce special mixtures to suit the customer’s individual requirements. The details of each recipe are stored in our computer system and once the recipe number has been entered, computer-controlled mixing plants produce the required substrate with maximum reliability, accuracy and homogeneity. A representative reference sample is taken automatically during the production of each substrate batch.

Documentation: The mixing plant delivers a comprehensive production record for each batch, stating the quantities of the individual substrate components that were used, the weight by volume and the produced quantity. The reference sample from the production process is taken to our in-house laboratory where it is visually inspected, analysed and then stored in a cool place for six months.

Here you can read the second part of our value chain.