Carbon footprints for individual nurseries and crops

Klasmann-Deilmann has developed a calculating tool for determining the carbon footprint of a horticultural company. This measure discloses not only emissions relating to energy consumption, seed, fertilisers and pesticides, as well as packaging and growing containers, but also the proportion arising from substrate use. The calculating tool also converts a nursery’s emissions into a figure for a given cultivated crop. A number of important findings are presented here.

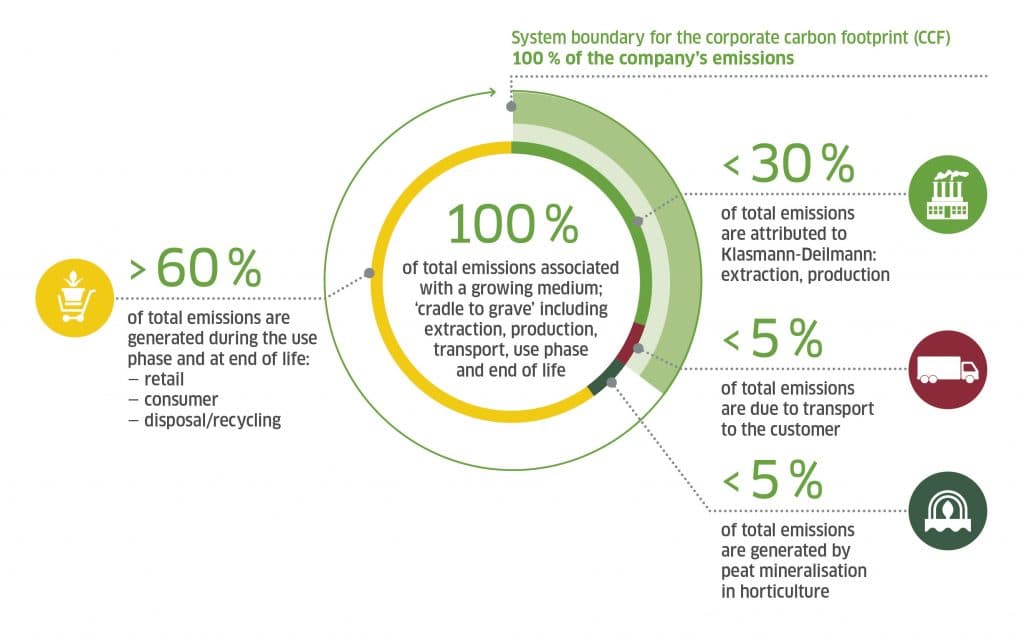

It was in 2013 that Klasmann-Deilmann first calculated a corporate carbon footprint (CCF) that factors in all emissions generated throughout the Group. The CO2 levels determined for this purpose can subsequently be converted into a product carbon footprint (PCF) for a given growing medium.

The methodology underlying the carbon footprint – this footprint being verified to the ISO 14064 standard – has now been developed further to create an application for horticultural businesses. The new calculating tool can now also be used to determine the CCF for a given nursery and the PCF of each crop cultivated there. Firstly, all relevant factors are identified in detail and fed into the calculations. These include consumption of electricity, natural gas, petroleum and coal, the seed used, fertilisers and pesticides utilised, and packaging and growing containers. The use of growing media, including their transport to the nursery, is also precisely factored in.

The CCF subsequently determined by the calculating tool enables a given horticultural business to develop its own strategy for reducing emissions and to assess this over several years. Potential parameters here may include the business’s heating strategy or the use of substrates with a higher proportion of alternative constituents. Specialists at Klasmann-Deilmann provide active ongoing input into the calculation process for the carbon footprint concerned.

“Sustainability is playing an increasingly important role for the major food corporations,” comments Moritz Böcking, Managing Director of Klasmann-Deilmann. “We are keen to equip not only ourselves but also our customers for the demands of the future. Those able to account for how environmentally and climate-friendly their products are have an additional competitive advantage, since retail consumers and wholesalers are paying increasing attention to responsibly produced goods and reward sustainable development.”

Calculating tool: trialled in cooperation with two nurseries

The calculating tool was developed in collaboration with Cologne-based Meo Carbon Solutions GmbH, and trialled in close cooperation with two nurseries in Germany. mk jungpflanzen gmbH, a propagator of young vegetable plants and part of the Peter Stader group, and ornamental-plant grower Irßlinger GmbH & Co. KG provided operational data that were then processed using the calculating tool. At the same time, both nurseries helped to design the tool such that it reflected the realities of a horticultural company.

Firstly, corporate carbon footprints were determined for both nurseries. The outcome was then converted to give product carbon footprints for the relevant individual crops – lettuce, leaf lettuce, lamb’s lettuce, cabbage, herbs, leek, celery and poinsettias – raised in either trays or press pots.

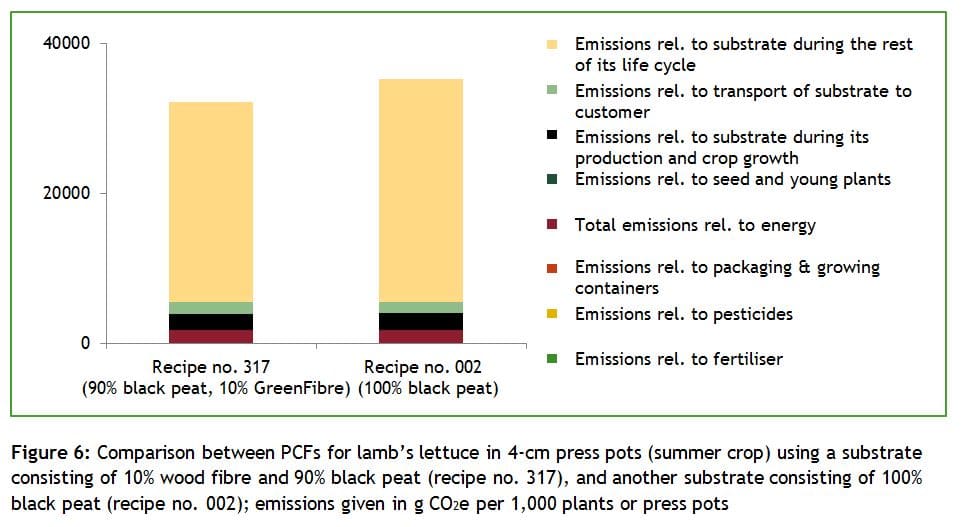

The following recipes were among those used as substrates (produced by Klasmann-Deilmann) in propagating the young plants and for calculating the carbon footprints.

- Recipe no. 002, consisting of 100% black peat, produced in northern Germany

- Recipe no. 317, consisting of 90% black peat and 10% of the GreenFibre wood fibre product, produced in northern Germany

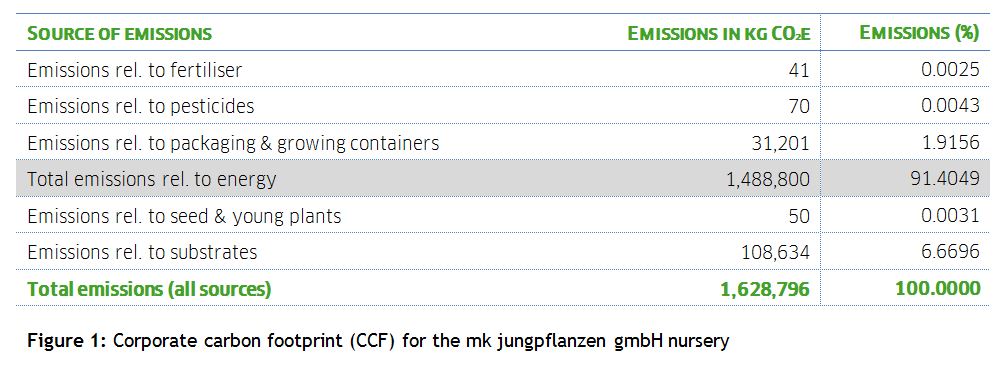

CCF: bulk of emissions is from energy consumption

All major emissions factors are included in the corporate carbon footprint for a horticultural company. The carbon footprint shown in Figure 1 was prepared for the mk jungpflanzen gmbH nursery: here, energy consumption accounted for by far the greatest proportion of emissions.

Peter Stader

“We have been addressing the issue of sustainability and careful use of resources for quite some time now. This includes, of course, the debate on peatlands and their exploitation, as peat is – along with energy – the biggest single input in the production of our young plants. It was Klasmann-Deilmann who drew my attention to carbon footprinting at the 2017 IPM trade fair; they gave us the opportunity to analyse our company. We fully appreciate, of course, that the absolute figures – taken individually – are highly abstract and not particularly meaningful. However, what this exercise fosters within our company is awareness of the issue: what can we achieve through the careful use of the resources we still have? Apart from the substrates we utilise, there are many other aspects that merit consideration.”

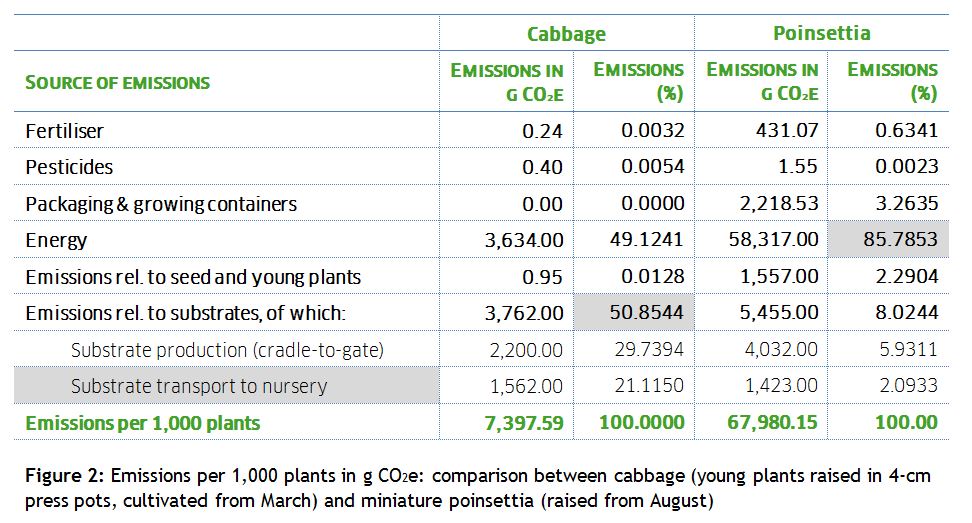

PCF: bulk of emissions is from energy consumption

A product carbon footprint (PCF) factors in all major emissions sources. Figure 2 compares emissions for 1,000 young cabbage plants grown in 4-cm press pots (cultivated from March) at the mk jungpflanzen gmbH nursery with emissions for 1,000 miniature poinsettias (cultivated from August) at the Irßlinger GmbH & Co. KG nursery. Because the crop is grown in a heated greenhouse, energy consumption accounts for the greater part of emissions arising from poinsettia production. For young cabbage plants grown in press pots, however, just over 50% of emissions relate to the substrate. For both crops, an appreciable proportion of emissions arising from substrate consumption results from transport of substrates to the nursery.

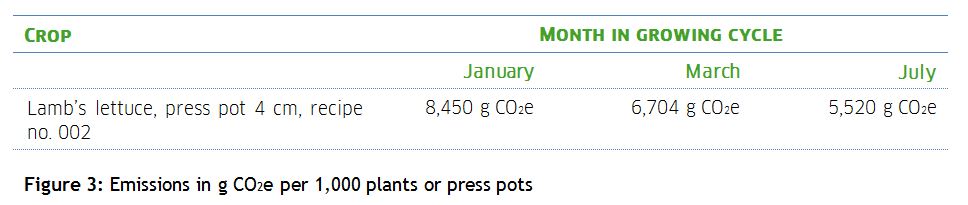

Seasonal effect: emissions much lower in summer

The PCF per 1,000 plants (e.g. cabbage, lettuce) or 1,000 press pots (e.g. lamb’s lettuce, herbs) depends in part on seasonal factors. Figure 3 shows that winter crops cause higher emission levels than those grown in summer, this being related to weather conditions ( = greater energy consumption) and light levels ( = longer growing cycle in the cold season). There is a rule of thumb which states that substrate-related emissions account for 45% of the total in winter, as energy consumption is relatively high. In summer, this proportion increases to 75%, since less energy is used.

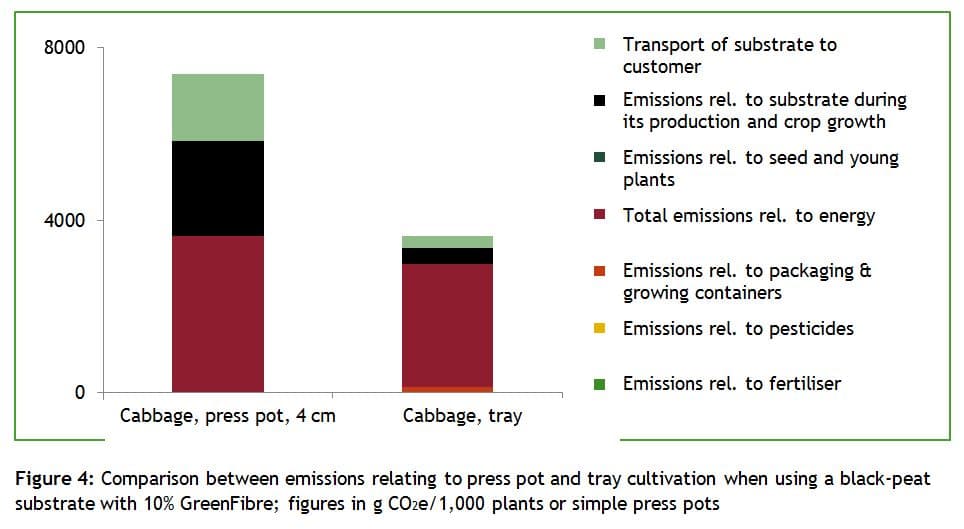

Trays reduce both amount of substrate needed and emissions

Figure 4 illustrates that, when plants are sown and propagated in press pots, resultant emissions are considerably higher than for tray-grown crops, as more substrate is required. However, this comparison is dependent on the size of the press pots and tray cells used. As substrate utilised in press pots is highly compacted, larger amounts are consumed per plant, leading in turn to greater substrate-related emissions.

In the comparison used for calculation purposes, tray cells were considerably smaller than press pots. This means that less substrate was needed per plant and that there were more plants per square metre of greenhouse space: tray-cultivated cabbage plants were grown 295 to a box, compared with only 140 per box cultivated in press pots. This lowered emissions relating to substrate and energy. Emissions relating to the plastic trays used, and the longer growing period, had no appreciable impact on the overall calculation.

Thomas Hanenberg and Katrin Irßlinger

“For us it was a valuable experience and our first engagement with this issue. Perhaps we are somewhat ahead of the curve right now; nevertheless, the environment and sustainability are issues of growing importance for retail consumers – and, therefore, hence for our customers, the retailers, as well. Presentation of our greenhouse gas performance showed it makes sense for us to break down this footprint to the individual product level. This enables us to use this key performance indicator as a marketing asset.”

Alternatives: lower cumulative end-of-life emissions

In the calculation of both the CCF and the PCF described here, the focus is on a nursery’s value chain including the operational inputs it buys in. This is a cradle-to-gate scenario calculation ending at the time when crops leave the premises of the nursery and are, for example, resold.

In terms of the PCF for a given crop, however, broader considerations are advisable, since the substrate used will fully break down over time and release further quantities of CO2. In this regard, it does not matter in which context the substrate decomposes (e.g. on farmland or in a retail consumer’s garden). What is important are the emissions that must be additionally attributed to a given crop if its entire life cycle is taken into account (end-of-life approach). For the crop as product, emissions accrue along the value chain that have nothing to do with the nursery itself, including transport-related emissions and those relating to the substrate in which it was grown and in which it may remain until it is composted.

Especially when this all-encompassing end-of-life approach – which considers a crop over its entire life cycle – is adopted, alternative constituents in a growing medium have a positive impact as they help substantially reduce a crop’s PCF. This is because renewable substrate constituents themselves generate no emissions since, in cyclical fashion, they first absorb carbon from the air before subsequently releasing it. Therefore, emissions can be attributed only to the associated production processes (e.g. producing fibre from woodchips). Peat, however, is considered a fossil resource for which emissions from its decomposition are fully taken into account.

In the cradle-to-gate approach, however, alternative constituents have only a slight impact. This is due to the brief period during which the substrate is used in the nursery. Accordingly, only a small proportion of emissions arising from the substrate are generated in the nursery itself. To a large extent, the actual decomposition process takes place at the later stages of the value chain. Figure 5 depicts this in a simplified manner.

Summary conclusions

The PCFs determined in this project for different crops under different cultivation conditions resulted in the following main findings:

- The bulk of emissions in nurseries results from the use of fossil fuels and substrates;

- Winter crops cause higher emission levels due to (weather-related) greater energy consumption;

- When plants are sown and propagated in press pots, this tends to lead to higher substrate-related emissions than for tray-grown crops;

- Cultivation of young vegetable plants under cold-house conditions gives rise to relatively high emissions relating to the substrate used;

- The use of a blocking substrate with a share of 10% of the GreenFibre wood fibre product can reduce PCF (per 1,000 plants) under the end-of-life approach.

The goal is increasing awareness of climate issues in commercial horticulture. “We are very keen to see nurseries holding more in-depth discussions with our experts,” says Moritz Böcking, “with a view, if possible, to switching to substrates that have a lower carbon footprint.”

Authors

Dr Jan Köbbing, Land Use + Sustainability Management; Klasmann-Deilmann GmbH

Josef Rehme, Advisory Services + Quality Management, Klasmann-Deilmann Service GmbH

Dirk Röse, Corporate Communications, Klasmann-Deilmann GmbH