Dear customers and business partners,

Commercial horticulture is undergoing profound changes. Digitisation, sustainability, profitability concerns and globalisation call for new, integrated overall approaches that modern growers can adopt. We are actively moving forward here, providing forward-looking solutions. With digital solutions, modern growing systems and new substrate constituents, we have more to offer your business, and many further innovations are being vigorously pursued. Our aspiration is that each new development will represent a tangible advancement, simplify your day-to-day operations, make your crop management more reliable and boost the success of your business. In order that our product launches go smoothly everywhere – especially in this time of coronavirus – we will also use digital training formats such as online seminars in the future.

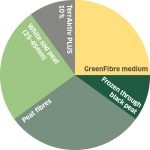

And there is another good reason to stay innovative: to put it plainly, commercial horticulture needs more options. Demand for growing media and cultivation systems will see a strong increase in the years ahead due to global population growth and a rising demand for healthy foodstuffs. Given the limited resources, available options will need to be fully exploited if the required substrates and systems are to be produced. In the light of this, we have set ourselves the target of increasing the share of alternative constituents of our total production to 30% by volume by 2025. The era of purely peat-based growing media is over; the future path will involve an ever-increasing range of alternative raw materials and new cultivation methods.

This objective is in line with the latest developments in the European Union. The agenda is clear: conserving resources, securing supply, minimising waste, doing business sustainably and attaining climate neutrality by 2050. With the variety of our substrates and their tremendous benefits for people all over the world, we will help to achieve this – at all times prioritising our quality standards and the reliability of supply to our customers.

We wish you, your families and your company all the best. Stay healthy and safe!

Best wishes,

Moritz Böcking, Bernd Wehming

Managing Directors of the Klasmann-Deilmann Group