We make it happen: Deliverability and quality in harmony.

The horticultural sector is undergoing major change. Nurseries are increasingly faced with higher demands for sustainable and resource-conserving production processes. Our growing media must also fulfil these new requirements. For this reason, alternative new raw materials will play an even more important role in the future. In addition, the demand for high-quality growing media will increase internationally in the coming years and will have a global impact on the availability of raw materials.

However, the disrupted supply chains of recent years have also shown that agility and comprehen- sive expertise in modern substrate solutions are the key success factors for being able to deliver reliably. Reasons enough for Klasmann-Deilmann to take an even more active approach on behalf of the entire industry. We are setting new standards in the use of modern substrate mixtures and in ensuring a stable supply of raw materials.

„We will ensure that our customers continue to receive the best possible quality growing media at all times.“

Eric Lekkerkerk, Commercial Director

Your plus in benefits – what we can do for you:

Long-term planning: Production quantities and availability of raw materials

We plan the production quantities of our substrates years in advance. This also includes the reliable provision of all required substrate raw materials. This means that you are always on the safe side with us. And because quality and availability go hand in hand at Klasmann-Deilmann: We are a member of RHP. This ensures that you only receive quality-tested and reliable substrates for every crop and every field of application.

Own production: Substrate constituents

We produce all constituents for our substrates ourselves. Whether with our own facilities or with our own raw materials companies within the Klasmann-Deilmann Group. From peat and wood fibre to coco products and perlite to specialised bark and compost materials: At Klasmann-Deilmann, everything comes from a single source and is always available in tested quality for the production of your substrate.

Systematic protection and expansion: Peat resources in the Baltic region

We use alternative substrate components and their advantages for plant cultivation in our substrates. Availability is guaranteed for years to come, e.g. for our structurally stable potting and propagation substrates. This preserves valuable peat resources. The production of blocking substrates with Baltic black peat is based almost exclusively on RPP-certified responsible use of peatland. This also applies to future extraction areas.

Consistent investments: Production capacities and filling systems

Demand for substrates is increasing worldwide. In order to continue to supply you with the highest quality at short notice – even in the peak season – we are investing more in new production sites and state-of-the-art process equipment. Decentralised, international and with production partnerships. Filling always complies with the European standard EN 12580. This ensures reliable filling volumes in all packaging, even after loosening in your nursery.

Increased use: Circular raw materials

Our GreenFibre® wood fibre and our TerrAktiv® green compost are outstanding examples of the successful production and use of wood-based raw materials and organic materials from the recycling industry. We have been developing substrate constituents for over 30 years. For the best cultivation results and with a high degree of sustainability, which enables a significantly reduced ecological footprint of your substrate.

Intensive development: tomorrow’s solutions

Whether modern cultivation systems, the development of specialised compost and mulch material, the commercial use of sphagnum farming or innovative polymer technology: We have long been working on the pioneering product solutions of tomorrow. And with the Growcoon propagation system and Nygaia – the substrate of the future – you are already keeping pace with modern horticulture in an ever- changing world.

Decentralised production: wood fibre

We operate 12 wood fibre plants worldwide. More are being planned. This allows us to react flexibly to the increasing demand for our GreenFibre® wood fibre at any time. We have secured the wood chips required for production through exclusive, long-term contracts. This means that you benefit from our decentralised net- work in times of shortage of wood raw materials.

Higher availability: substrate compost

MWith Olde Bolhaar Eco- service B.V., we have integrated Europe’s largest and leading producer of substrate compost into the Klasmann-Deilmann Group. In this way, we ensure the increasing demand for high-quality substrate compost. The production capacity for composted substrate constituents can therefore also be expanded as required in the future.

Developed further: bark humus

TerrAktiv® bark humus is produced on a large scale at AGS in Australia, Olde Bolhaar Ecoservice B.V. and at our sites in Lithuania and Ireland. Thanks to its good physical properties and high microbial vitalisation, it offers a wide range of possibilities for use in growing media. Here, too, we are constantly expanding our production capacity.

Exclusive access: coco raw materials

Thanks to our distribution partnership with Shakti Cocos B.V., we have direct and exclusive access to very large quantities of coco raw materials in India and Sri Lanka. This will secure the required quantities for the Klasmann-Deilmann Group for the coming decades.

Own production: perlite

We have been producing our own high-quality perlite at our Silute site in Lithuania since 2022. This means that we are completely independent of external suppliers and thus increase the security of supply and price stability for this valuable substrate constituent.

Remains convincing: peat

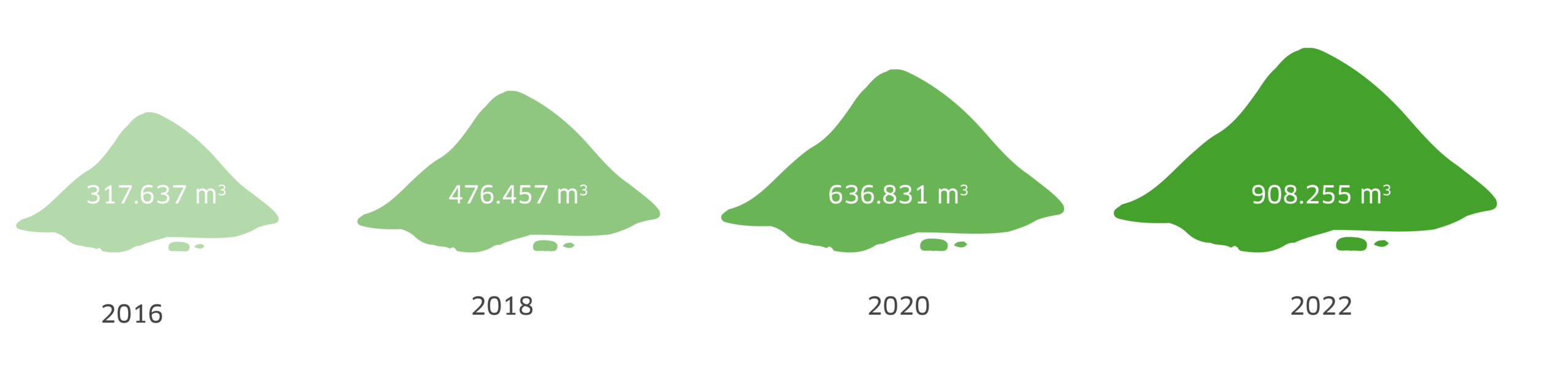

Due to its many positive properties, peat remains the main component of professional growing media. However, modern substrates are increasingly using alternative raw materials. One of the reasons for this is to conserve and preserve the valuable peat raw materials for the coming years.

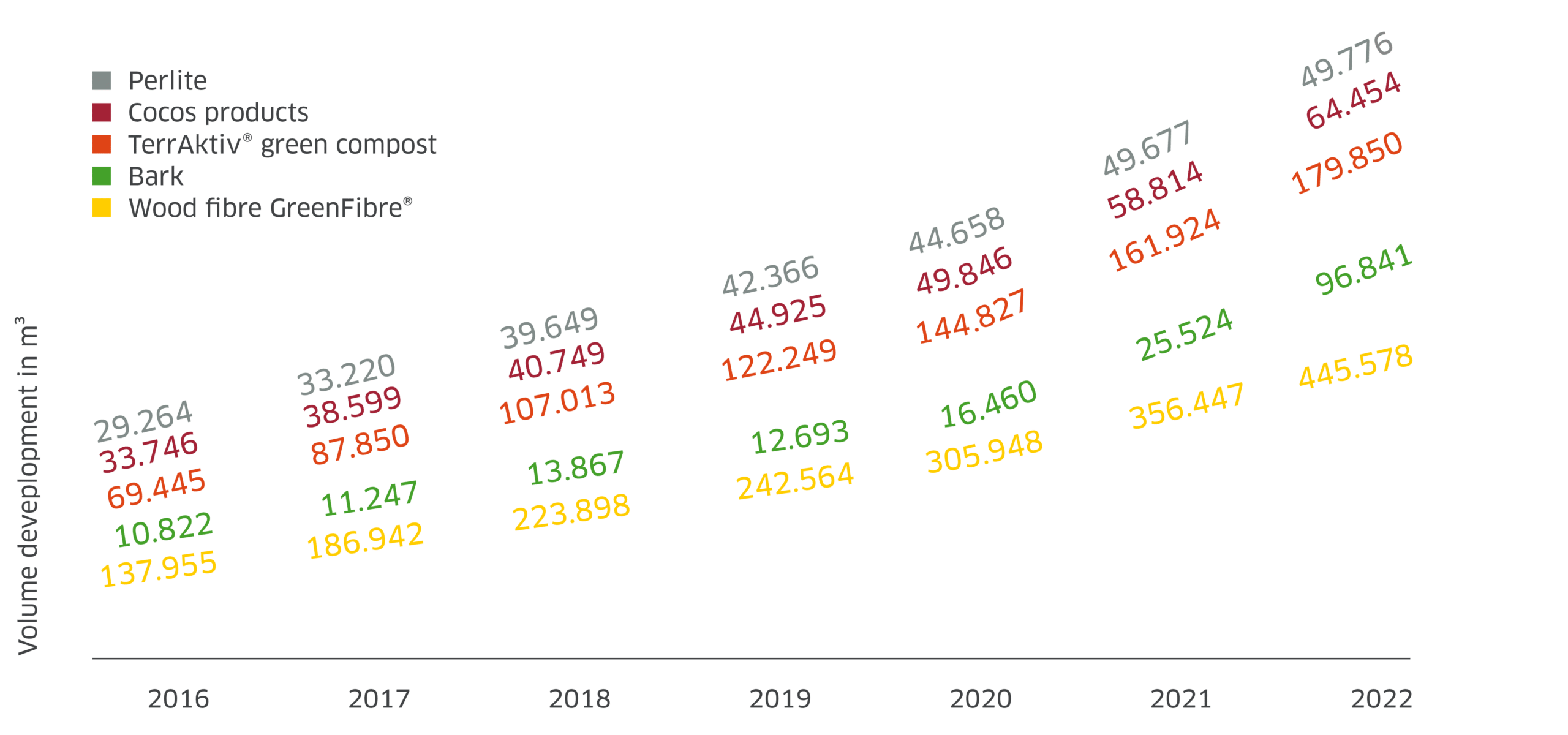

Volume development of alternative raw materials in the Klasmann-Deilmann Group since 2016

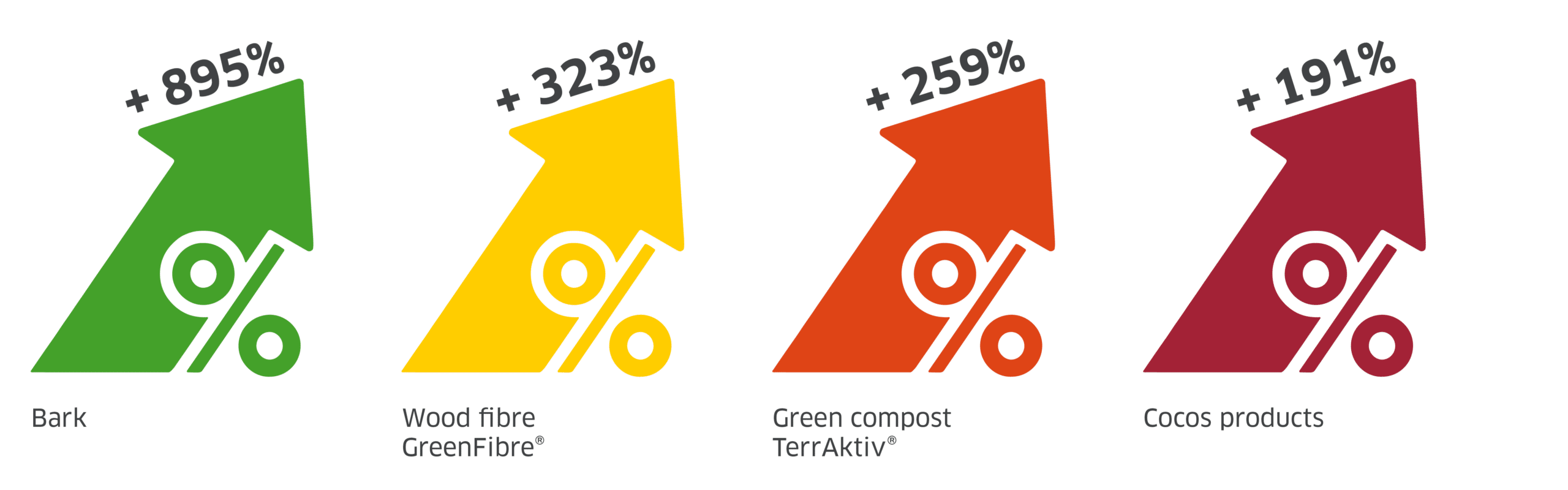

Increase of selected alternative raw materials for use in substrates (period: 2016 to 2022)

Peat is still the main component in the production of professional growing media, but is increasingly being replaced by alternative raw materials. And all this without compromising on sustainability and crop security. In this combination, Klasmann-Deilmann creates unique substrates that meet all the requirements of professional horticulture: our Advanced Substrates.

Good to know: Our own peat raw materials

Although peat extraction in Germany is currently being ended as planned, we are still very well prepared with our own peat raw materials in Lithuania and Latvia for many years to come, so that no shortages can occur. Our extensive own peat extraction areas will give us reliable access to high-quality white and black peat for decades to come.

Enough for everyone: Our own trade in raw materials

Through our raw materials trading company Bol Peat B.V., we have also been strongly involved in the raw materials business for many years. This enables us to offer peat and alternative raw materials on the open market. If required – for example during seasonal peaks or due to adverse harvesting conditions and raw mate- rial shortages – we use these raw materials primarily for our substrate customers and are therefore able to supply them at all times. A significant strength of the Klasmann-Deilmann Group.

Twice secured: Our own quality raw materials

We remain uncompromising in terms of sustainability and crop security for all the substrate raw materials we use. Highest quality will continue to be our standard in the future. Our products and manufacturing processes are therefore subject to RHP quality certification. You can also rely on this.

Consciously certified: Our special responsibility for peat

Almost all the peat raw materials used in growing media from Klasmann-Deilmann come from responsible peat utilisation and are certified accordingly on the basis of „Responsibly Produced Peat“. This also ensures that the areas are returned to nature conservation quickly after utilisation and are soon rewetted. This creates protected natural areas and, above all, important CO2 sinks. An important contribution to active climate protection. All company processes are also certified in accordance with the ISO 14001 environmental standard.

Be on a par with the future:

Advanced Substrates by Klasmann-Deilmann

With Advanced Substrates, Klasmann-Deilmann has developed a modern product range to use valuable peat raw materials even more carefully and to preserve the available resources for the future.