Go organic. We go ahead.

IPM 2019: Klasmann-Deilmann moves organic horticulture forward | Certified by Ecocert® | Wetting agent for organic cultivation | Growcoon with dispenser and approval for organic use | New possibilities for blocking substrates | Substrates for soft fruit

Sales of organically grown vegetables, fruit and herbs have reached a high level. Demand is continuing to increase; it appears this positive trend will not be ending any time soon. And organic is a firmly established market segment at Klasmann-Deilmann. As the leading producer of organic substrates, the company assumes a key role early on in the value chain.

New: Certified by Ecocert®

In view of the further increase in demand for organic substrates, especially in international markets, Klasmann-Deilmann has made changes regarding its organic certification. As of the start of 2019, the company’s production of organic substrates is regulated by international certification organisation Ecocert®. Ecocert® now inspects and certifies Klasmann-Deilmann’s recipes for organic substrates, currently numbering more than 200, in accordance with the EU regulation on organic production. As the Ecocert® Group is a high-profile certification body that operates worldwide, we expect the confidence placed in Klasmann-Deilmann by international partners and customers to grow still further.

New: Wetting agent for organic cultivation

Klasmann-Deilmann is introducing a new, highly effective wetting agent for all organic substrates, derived from plant-based raw materials without surfactants. This agent:

- aids initial wetting of potting and blocking substrates used in organic cultivation;

- improves irrigation using ebb-and-flow systems, especially with potted herb crops;

- simplifies water management and hence improves crop management in horticultural businesses;

- makes ‘drier cultivation’ possible and reduces the pressure of soil-borne fungal infestation.

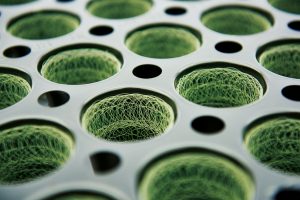

New: Growcoon with product-specific dispenser and organic approval

The Growcoon is finding a continuously expanding customer base in various horticultural segments worldwide. This propagation system is proving especially effective in the rooting of cuttings, in the growing-on of young plants from in vitro systems, and in the use of hydroponic cultivation. The main benefits of using Growcoon for propagating young plants are shorter growing cycles, robust plant health, greater root ball stability and – especially with delicate seedlings – lower failure rates.

Many different standard and special sizes are available, as are trays for use with these sizes, which means the Growcoon can be used in all established propagation systems and with different trays. A dispenser specially designed for the Growcoon is now sold by Dutch company Flier Systems. The dispenser is located upstream from the tray-filling machine and automatically places the Growcoons in trays. Alternatively, this can still be done manually.

Growcoon is a biodegradable plug with a flexible, open structure. When used in propagation systems, it holds the propagation substrate together and, in this combination, forms a stable root ball. It is made of food-safe components and features the OK COMPOST label certifying it to the EN 13432 standard. This means, for example, that the Growcoon does not entail any pollution risk with respect to farmland, people or the environment, and leaves no harmful residues.

The Growcoon was recently included in the ‘Dutch input list’ maintained by Netherlands-based organic control body Skal. This lists products approved for use in organic agriculture in the Netherlands. The Growcoon thus also complies with the European organic-farming regulation.

Growcoon is produced by Dutch company Maan BioBased Products B.V. The Klasmann-Deilmann Group holds the global distribution rights to this product.

New: Proven blocking substrates available as new blends

Successful combination of frozen black peat and our GreenFibre wood fibre product has laid the foundation for a new generation of blocking substrates. Whereas, previously, the only recipes regarded as being a reliable basis for stable press pots were those based solely on black peat, now additional benefits can be achieved by the use of alternative constituents. Addition of up to 20% of a specially screened fine form of GreenFibre results, at high substrate yield, in press pots of even greater stability while also reducing substrate weight. ‘Potgrond H 85 with GreenFibre’ (recipe 078), a substrate blended in this way, is now firmly established within Klasmann-Deilmann’s range of blocking substrates.

The use of raw materials from the Baltic region has also become well-established as it makes for lighter blocking substrates and yields equally good crop performance. For example, blocking substrate ‘Potgrond H 50 with GreenFibre’ has not only a high proportion of wood fibre but also a specially prepared white-peat component with a ‘blocking’ function that combines with the wood fibre in the press pot, thus ensuring optimum stability for automatic planting-out. Air capacity has also been increased, ensuring enhanced root development.

Press pots, a proven growing system, will remain of great importance for the young-vegetable-plant segment. Long-term reliability of supply for blocking substrates is ensured, thanks to the use of new raw materials. Other major Klasmann-Deilmann customers have already announced they will switch to blocking substrates containing GreenFibre in 2019.

New: Specialist substrates for reliable cultivation of soft fruit

With a view to continued growth in international demand for soft fruit, Klasmann-Deilmann has developed a compact range of specialist substrates for reliable propagation and high-yield growing-on of cultivated berries grown in pots and containers. These contain tried-and-tested substrate solutions, particularly for strawberries, blueberries, raspberries and currants in containers, produced using various raw materials: peat, coco pith (coir), GreenFibre and perlite.

The substrates ‘TS 4 soft fruit with perlite’ (recipe 496) and ‘TS 4 soft fruit with GreenFibre’ (recipe 497) are available for cultivation in containers or in substrate-filled gutters. There is also a peat-free blend called ‘Container substrate 3 soft fruit with coir’ (recipe 237), as well as a substrate blend – ‘TS1 propagation of soft fruit’ (recipe 881) – developed especially for growing young plants. In terms of their pH values and nutrient supply, these substrates have been precisely designed to meet the needs of berry crops. For example, they contain chelated trace elements to specifically ensure a reliable supply of iron.

“It was important to us to design a range of products that deliver reliable crop outcomes,” says Horst Kupschus, Managing Director of Klasmann-Deilmann Europe GmbH. “We also had in mind growers just entering this segment, for whom it’s especially crucial to have a dependable substrate like this.”

Klasmann-Deilmann provides horticultural businesses with an in-depth advisory service on all aspects of growing soft fruit. “This also applies to growers who are currently merely thinking about cultivating berry crops in the future,” says Kupschus. “Our specialists have drawn up guidelines bringing together the key facts. These will help them make an informed decision and, if they so wish, to enter this segment.” A manual in the ‘GreenNotes’ series gives basic guidance on cultivation, crop management, substrate use and fertilisation, helping new growers of soft fruit to get off to a good start.